Temat Textile

Main menu:

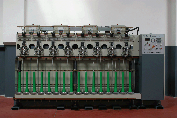

CX 2000

Prodouct

General Description

The CX 165 machine can produce standard chenille yarns. Its construction in units of 8 spindles each makes it possible to satisfy different needs of space and production. The application of electronics and the new concepts of mechanical

construction make it a highly reliable and productive machine. Constructed according to the most modern safety criteria and noise abatement standards for the protection of the operator, the CX 165 is at the same time convenient and flexible, and it requires very little maintenance.The traditional control system ensures high

reliability and versatility in the production of different yarns from one position to another. The use of large balanced pulleys, used to control both the spindles and the feeder heads, has increased productivity and made it possible

to reduce the mechanical transmissions.

Technical Features

The main head for movement of the rail is managed by an electronic programmer with total control of spindle formation, automatic stoppage of all positions when

spindle formation is complete and automatic deceleration to the speed set by the operator. Each unit consists of 8 spindles, and the head can control up to 15 units for a total of 120 spindles. Every pair of spindles has a 0.75 HP motor that stops in case of breakage of either of the core or effect threads relative to the position controlled. Each unit is complete with an autonomous electric system capable of controlling all the motors installed on it. Each unit is powered by connection to a bus duct installed along the entire machine. The spindle offset is 165 mm. The tube is 450 mm high. It is possible to install rings with variable diameter between 90 and 127 mm, depending on the count of the yarn to be produced. Spindle speed can

range from 6000 to 8500 rpm depending on the type of ring installed, while the feeder head can reach a speed of 18000 rpm. Maximum production speed is 14 mt/min. Calibers from 0.8 to 15 mm can be installed. On the same machine, a cutter with either rotating or alternating blade can be mounted. The machine is complete with a cone supply creel both for the core yarns and for the effect yarns.

It is also possible to mount special equipment for the production of discontinuous chenille or particular effects.